Dry Gas Seal

Support Equipment

Vidac has been supporting Dry Gas Seal testing since 2003 when we built our first fully automated API-692 tester. In order to test a seal, it takes more than just one of our testers.

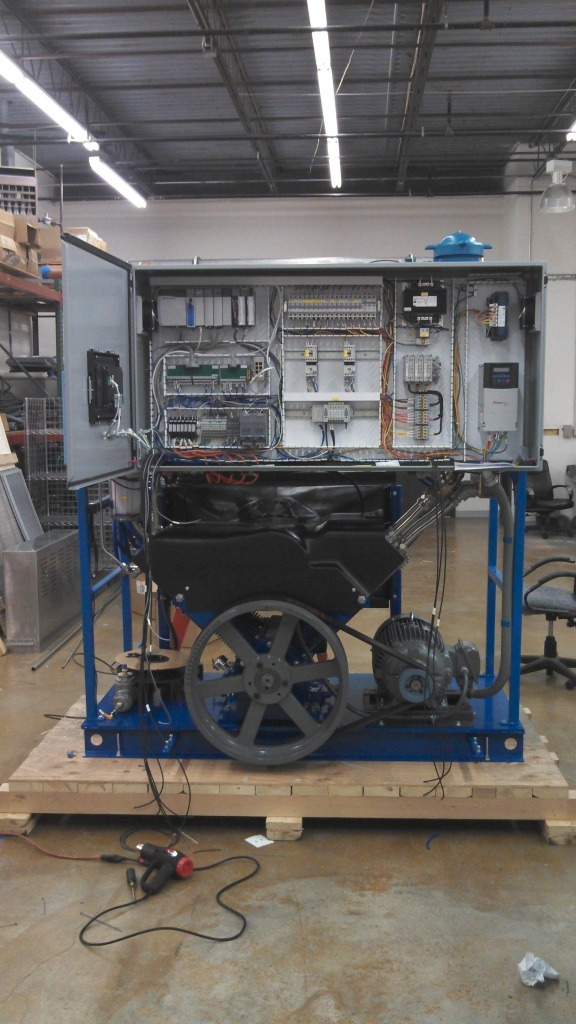

Compressors: We can help you integrate a compressor system with all sorts of options:

- Air-to-Water Heat Exchangers: Used to lower outlet temperatures, avoid room heating and permit much tighter packaging

- Stand alone operation.

- Variable Speed operation to limit heat load and maintain demand pressure.

- Redundant layout to switch the running compressor daily.

- Staged operation layout, so that the second compressor will only run in high usage times.

Dry Air Gas Boosters: We have integrated dozens of gas boosters and have used them in staged configuration to maintain very tight pressure output control.

High Pressure Storage: While we do not manufacture tanks, we can help with accumulator sizing and have many options on where to source them.

Filter/Driers: Additionally, we have much experience with implementing high pressure filters and dryers into the gas stream.

Torque Meters: We have also worked with various torque meter companies to be able to read high-speed torque directly before the gas seal so that there are no gearbox losses included in the torque measurement. All oil, lubrication and auxiliary equipment are included including temperature and vibration monitoring.

Helium Recycling: Since many dry gas seal test are conducted with Helium, we have successfully built systems to recapture, clean, separate and re-pressurize the Helium (or Helium/Air mix) for re-use in the test.

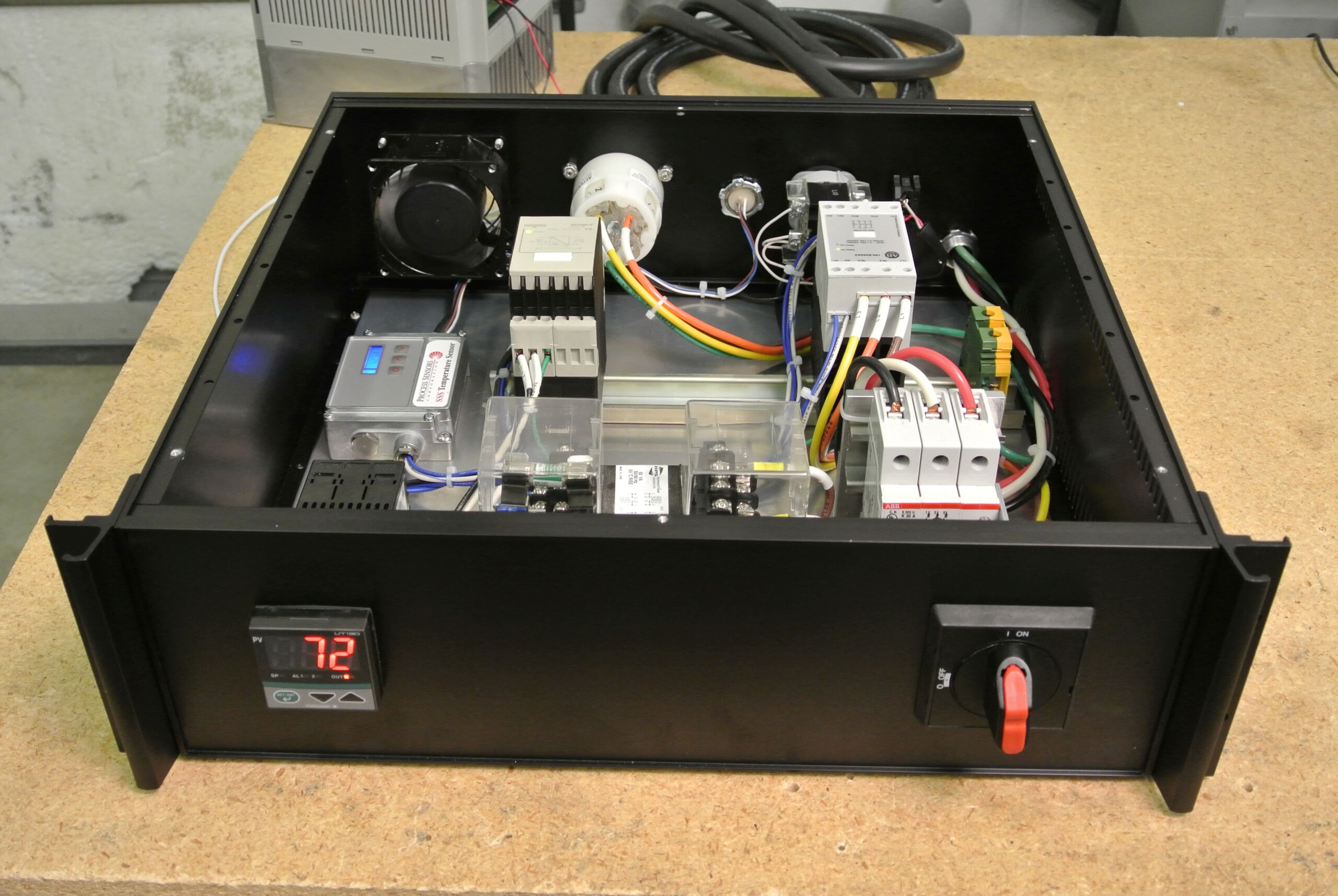

High Pressure Gas Heaters: We have built several very high pressure (800 BAR) heater systems to permit injection of very hot (300C) gas into the device under test. Additionally, we have built heater controllers that can optically read the rotating component temperatures inside the test vessel.