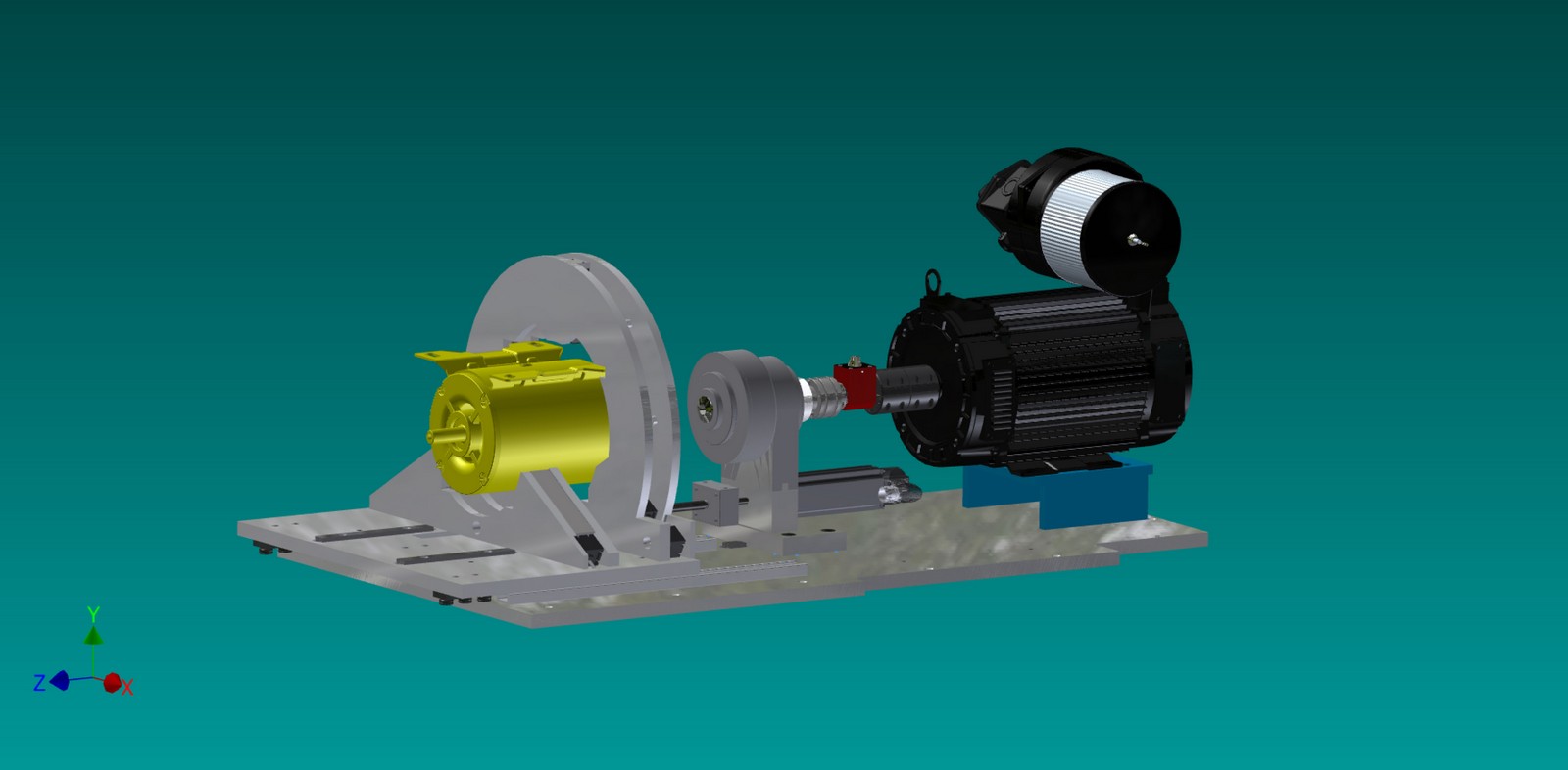

Motor Dynamometers

Motor/Generator Testers

Appliance motors are always evolving and the final testing of those motors gets more complicated every year. We build fully automated testers for domestic or offshore manufacturing facilities that can perform any amount of motor testing that you require with limited interaction by the operator.

Vidac can provide the following services:

- “Bump and Run” unloaded motor testing: We can verify that the motor electrically starts and runs unloaded within the current and power limits provided.

- “Full Load” motor testing: We can provide either a hysteresis dyno or a full 4-quadrant motor/load dyno to test from zero torque to full breakdown torque. Special pump curves and startup curves can also be applied.

- “Specialty” motor testing: We can back-drive a motor to verify wiring on PMM systems or to assist in encoder alignment.

- “Noise and Vibration” testing: Using accelerometers, microphones and a dead-silent test enclosure, we can help pinpoint bearing, alignment or gearbox issues.

*Of course, we can add Hipot testing, power analysis, oscilloscope or high-speed counter based encoder measurement to any motor tester.*

We take pride in being able to make the customers issues disappear.

CALL US

636.305.9179

-OR-